With over 30 years of history, always by your side.

Your sole partner for all production needs.

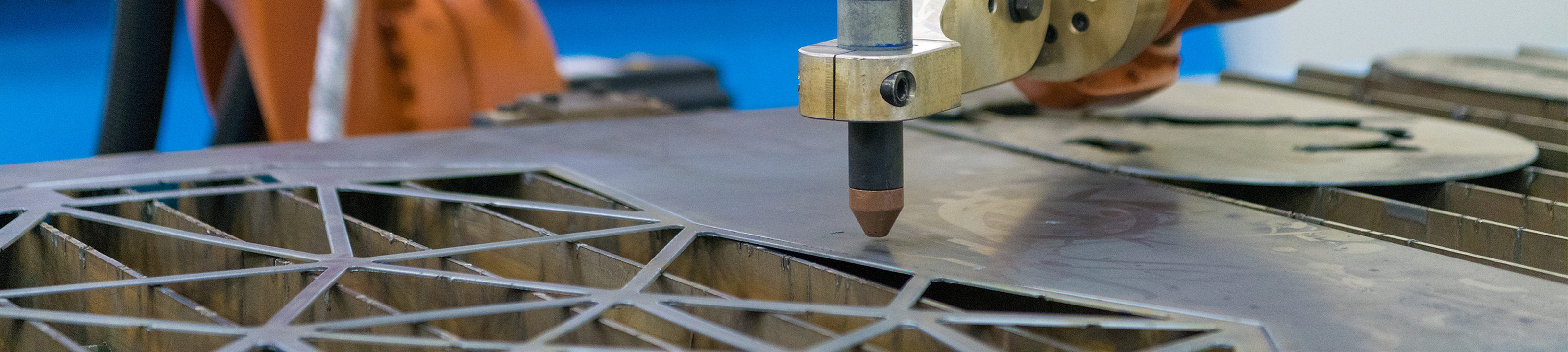

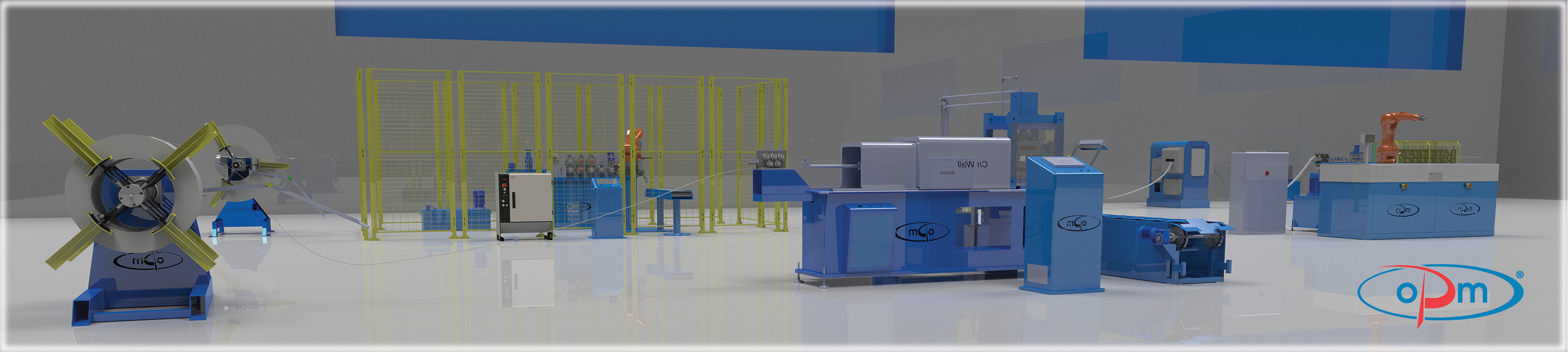

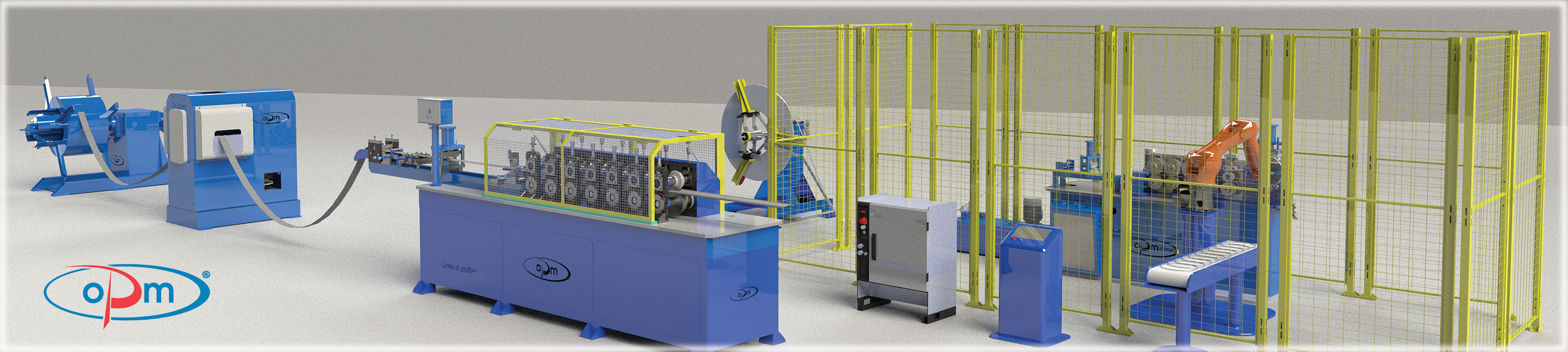

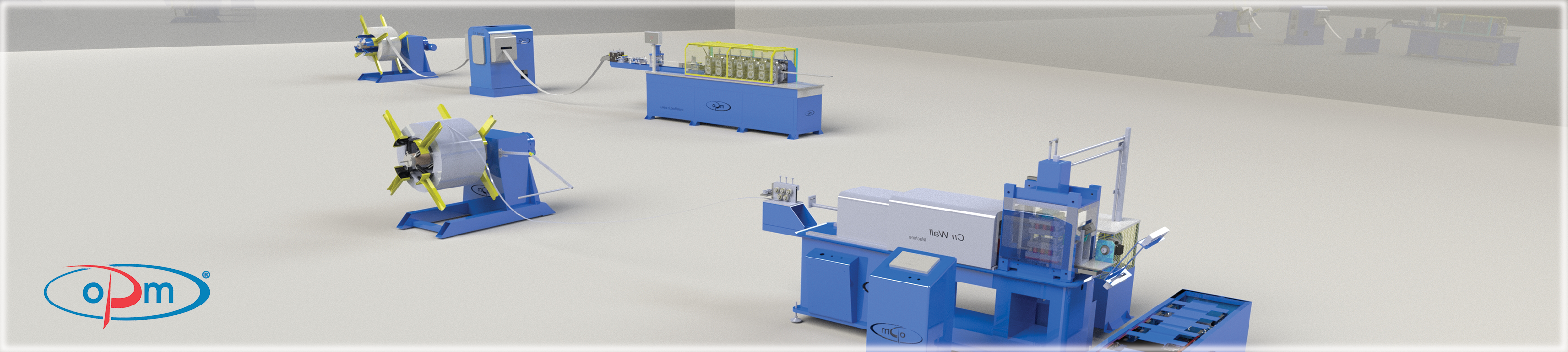

oPm is an industry specializing in the production of special hydraulic and pneumatic punching machines, both automatic and semi-automatic. These machines are designed for shearing, stamping, drawing, coining, pressing, and cutting operations, managed by PLC or CNC systems with user-friendly and self-learning software. Leveraging its extensive experience, oPm operates globally, standing out as a reference in designing and implementing complete punching lines and special systems for processing high-quality sheet metal and metal profiles across various sectors and markets.

The customer and their production logic are at the core of our business.

“The secret to meeting all our customers’ needs?

Building exactly the machines they want.”

From the research and design phase onwards, we collaborate with the customer to develop personalized solutions that bring their ideas, expectations, and needs to life.

Our state-of-the-art Research and Development laboratory is at your service.

The market’s recognition of our experience and growing success has allowed us to invest in research, innovation, and development.

Today, oPm is a partner with leading universities for research and the realization of innovative ideas and projects.

Our accredited research laboratory is a flagship of the oPm brand, serving as a reference point for innovative solutions, projects, and products for clients worldwide.

“Mast” Clemente Palmieri, the artisan turner who instilled a passion for precision mechanics in future generations, a passion that continues to thrive in the hearts of his children, grandchildren, and great-grandchildren, who remain passionate about this fantastic world, bringing Made in Italy to the world for 50 years.

Italy is rich in small and medium-sized enterprises highly valued in the global market for their exceptional technological expertise. We’re talking about excellent companies that have successfully combined Italian manufacturing ingenuity with the use of the latest technologies. oPm Srl, a leader in the construction of punching machines, automatic systems, profiling machines, and industrial robotics, is one of them.

Its leadership is tied to the entrepreneurial history of its founder, Engineer Palmieri, a pragmatic and visionary manager, who wanted to give the company a research laboratory connotation, earning recognition from both the Ministry and the Region. The “oPm” brand is now known worldwide for innovation, quality, and a wide range of solutions in the construction of special machines, technologically advanced and supported by cutting-edge robots and control systems.

“That’s why we’re always in continuous search of innovative ideas capable of simplifying and automating even the most complex operations of a production process.” This approach has given rise to cutting-edge machines and systems that have garnered significant interest in Italy and global markets.

“Specialization, the search for innovative and dedicated solutions, diversifying production – Palmieri adds – have always been the winning strategies to embark on the path of growth.” The real driving force of the company is its technical and design office, which over the years has conceived extraordinary systems and innovative solutions, particularly for the processing of closures for construction, aluminum profiles, metal roofing, chimney systems, and armored shutter systems.

The Campanian company was among the protagonists at Batimat 2015 in Paris, R+T Stuttgart, and Made Milano, where it previewed the latest oPm technologies. One of these is the Cn Sprint: a device born out of Italian ingenuity and technique, patented both in Italy and Europe, revolutionizing the concept of punching by combining tape advancement and stamping in a single motion.