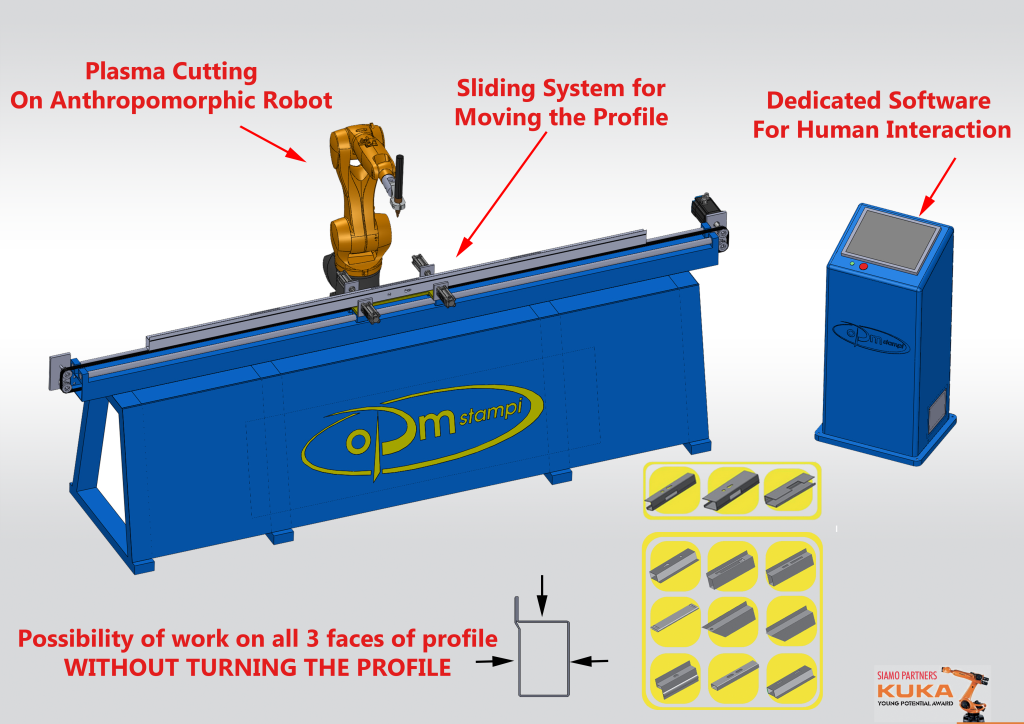

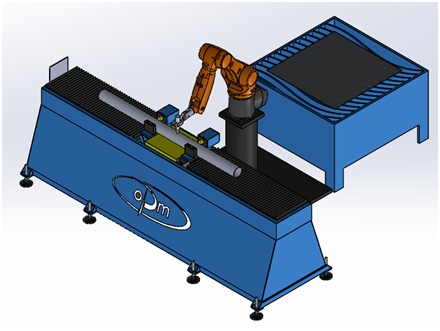

CN-ROBOT - Robotized working centre for plasma working on profiles

FEATURES

Robotized plasma cutting machine / working centre for perform lots of workings and cutting on profiles using cutting plasma robot. It can work on different profiles and materials, like iron, galvanized iron, inox and alluminium, with different lenght and shapes like rectangular, squared and circular section.

The working centre has got 7 axes and it can work on flat and inclined surfaces.

It is composed of an anthropomorphous ROBOT equipped with a plasma cutting head, and it’s capable to perform a wide number of workings.

Complete with CAM CAD software for the recognition of the profile, which allows the complete customization of the workings and therefore not to limit the possible workable operations.

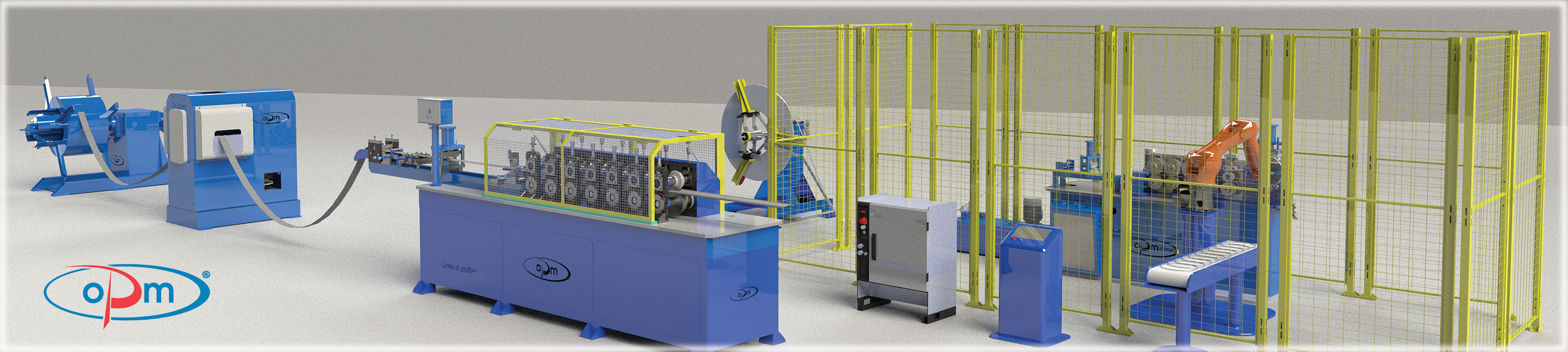

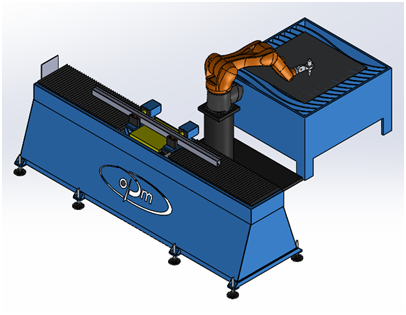

It’s also possible, adding another work bench, to work also metal sheets.

Because of the Dedicated Proprietary Software, it’s possible to set the lenght and the working needed on the faces of the profile, simply using an intuitive and user friendly interface.

The sliding cart will positionate the profile in order to receive it for moving the same to a retractable mechanical stop.

Activating the working, the profile will be moved automatically, in order to allow to the robot to work easily on the 3 faces of the profile .

So the times of esecution is in the range of few dozen of seconds, making the working extremely fast.

Also there is not necessity of any working tool for working also difficut parts of the profiles.

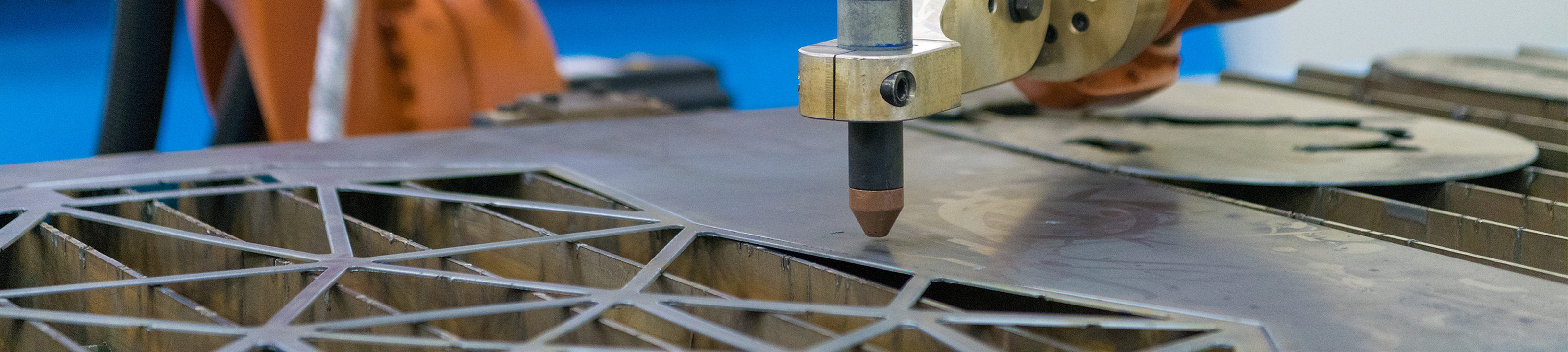

The inclination of the head of the robot allow to make workings on the diagonal, always with an excellent finishing of the product and also to work on tubulars.

The use of an high quality plasma generator allows to work with advancing of high speed, without heat up the profile that so will have no deformation, avoiding slimes and impurity in the cut.

The thing that the profile moves with the cart allows to have a reduced size of the plan, that so requires a lengh equal to the maximum lenght of the profile needed to work.

The plasma cutting system guarantee a wide possibility of customize the working for the exact industry application.

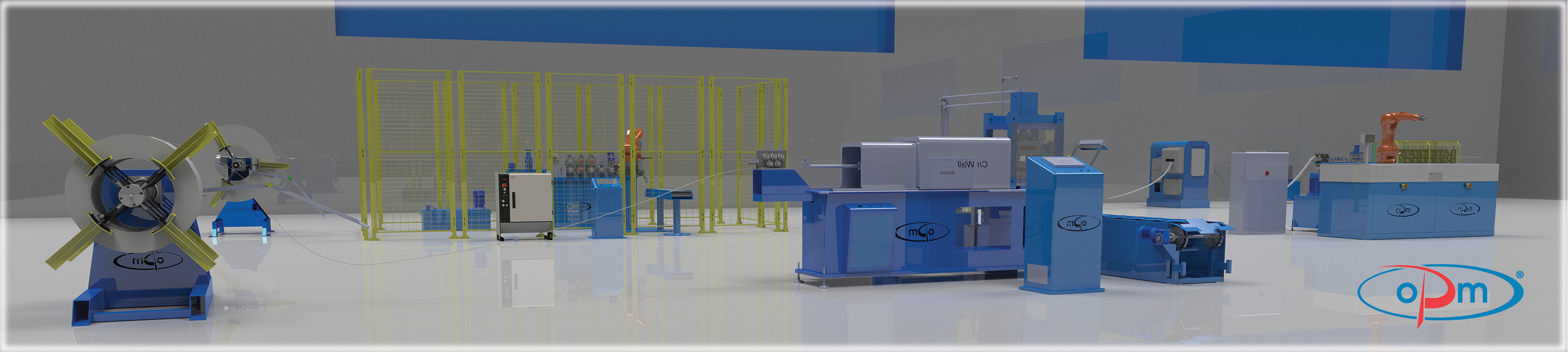

- Automatic machine/ Robotized plant for cutting performing various typologies of working.

- Equipped with anthropomorphic robot with plasma cutting head, capable of performing numerous machining operations

- Ownership Software

- Possibility of customize the workingIntegrated plasma cutting system for non-circular tubular tubes.

The system unlike other much more expensive cutting systems is both fast and versatile and capable of cutting even in non-planar situations. With a dedicated programming system you can cut in a few seconds the material with a good finish result, allowing you to make any shape you want. Fully automatic, reduces machining times and increases productivity.

Presented at the BATIMAT 2017 fair, held in Paris from 6 to 10 November u.s. the system has aroused comments and requests from visitors who have confirmed the likelihood, so that the company has in the portfolio executed on specific requirements that in this particular moment of stagnation of the markets help a lot of the productive activity.Unlike other plasma or laser cutting systems, the oPm system has advantages: a smaller size of the cutting machine, more productive efficiency, higher speed and precision of machining, lower cost of man / machine and consequently costs of processing.The PLASMA CUTTING system provides a wide range of customization options to center the exact industrial application.