UPVEL - Automatic machine to insert brush seals into aluminum roller shutters and mosquito nets guide rail

FEATURES

Seal Brush Threader

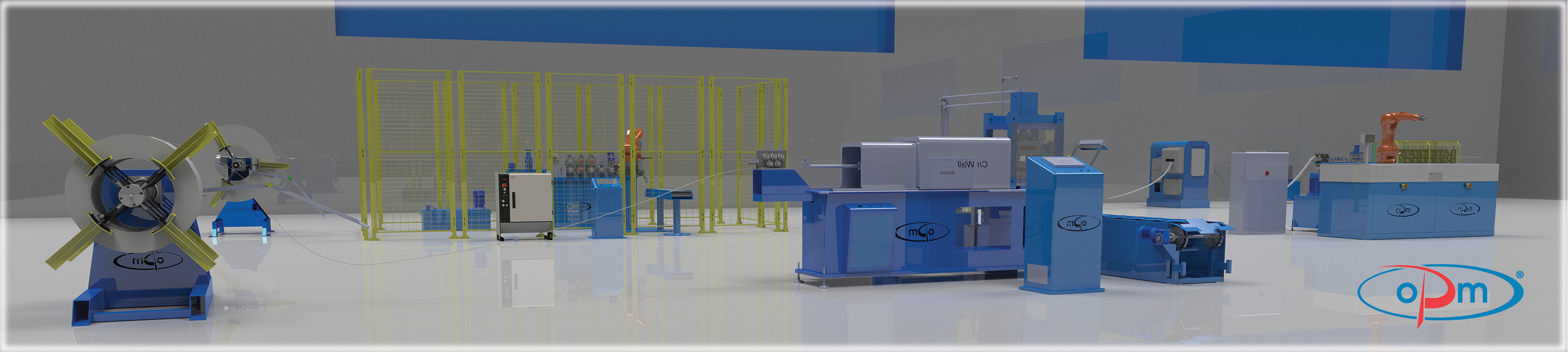

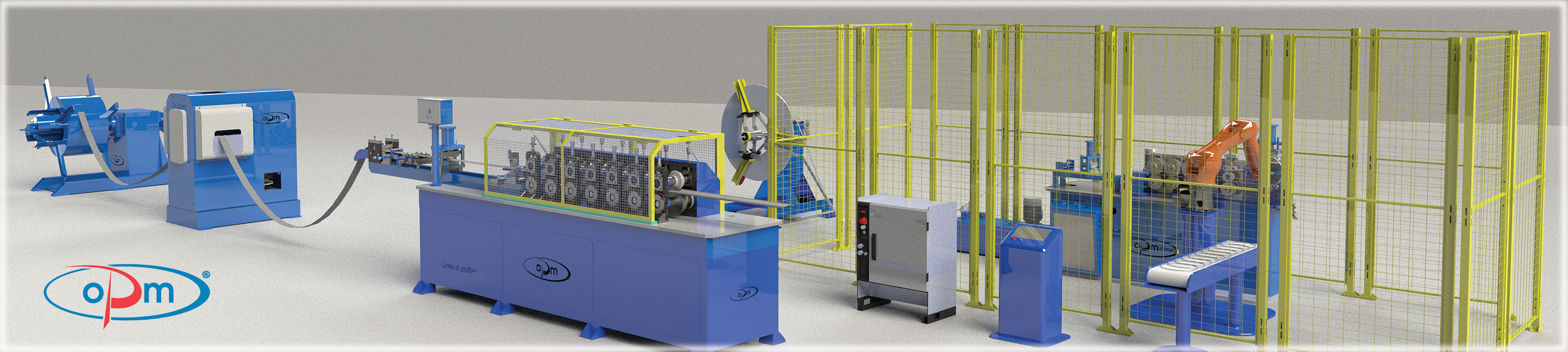

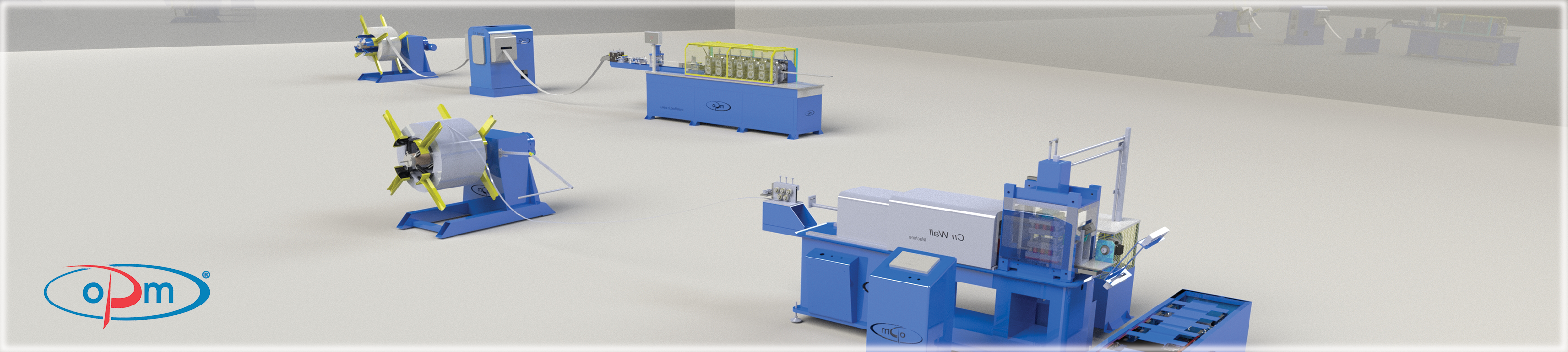

The oPm Seal Brush Threader automatic machine is designed for the easy insertion of brush seals into aluminum roller shutters and mosquito nets guide rail. The machine is versatile, allowing for the adjustment of centering tools to work with different shutter guide profiles using the same setup.

Compliant with CE regulations, the machine consists of a 7-meter base, a guide support platform, a centering system for the guide, a pneumatic system, a dragging carriage for inserting brush seals into the guides, a cutting unit, a support for brush seals coils, a PLC (Programmable Logic Controller), an electrical panel, a brushless motor, and active/passive protection systems.

According to the feasibility study, the workflow sequence is as follows:

1. Place the bar in the machine’s designated centering tool to align it with the brush seals for proper insertion.

2. Enter the bar length on the PLC and initiate the insertion cycle. The machine automatically inserts the brush seals into the first section of the shutter guide, dragging it along the entire length of the bar and cutting it near the bar’s starting point.

3. The completed bar can then be removed from the centering tool. The carriage automatically returns to the initial position via the PLC, and the process can be repeated.

The PLC allows for working with bars ranging from 30 cm to 6 m, accommodating both uncut and pre-cut bars. The machine is configured to handle various guide types with a maximum length of 6 m, using a dedicated centering tool for the specific guide.

To dissipate force during insertion and prevent breakage, brush seals coils are housed on specific unwinders that guide them into the machine. The PLC controls the brushless motor for gentle and tear-free brush seals insertion, minimizing waste.

Electrically managed through pneumatic solenoid valves, the machine is fully configurable to avoid wasting toothbrush seals at the bar’s ends. Waste reduction is further achieved through the flush cut during processing.

The entire workflow is controlled by a PLC, facilitating connection to factory computer systems for automatic fault detection and management.

The machine includes a custom electrical panel centralizing all electrical components in a dedicated cabinet, allowing for easy maintenance and immediate diagnostics during technical interventions.

An optional Industry 4.0 software enables real-time monitoring of production data and machine status on a computer.

The Seal Brush Threader machine is equipped with safety photocells and active/passive safety systems to comply with regulations. If the operator is within the work area, the machine stops. After loading new bars for processing, the operator leaves the area. The system has an emergency feature to halt the machine in case of undetected anomalies. Active and passive safety features ensure operator protection, certifying the machine as CE-compliant and eligible for legal benefits in Italy and Europe.