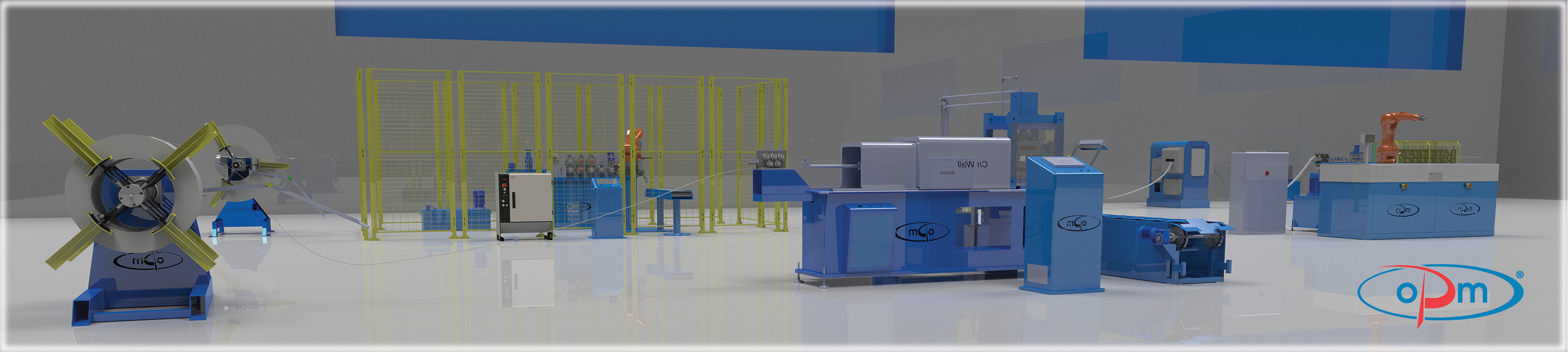

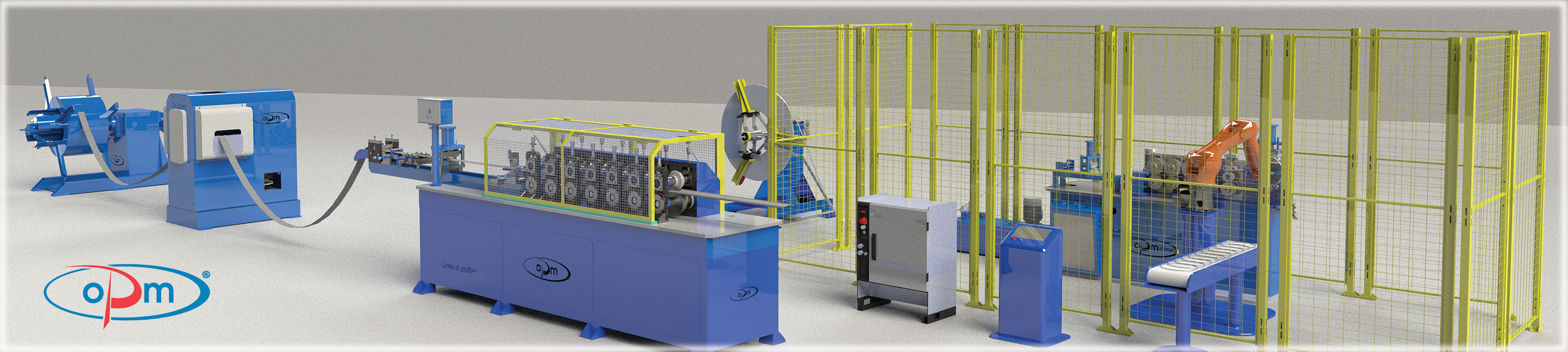

TICKNESS 1 mm - Roll Forming machine to produce U and OMEGA profiles

FEATURES

U and Omega Profiles

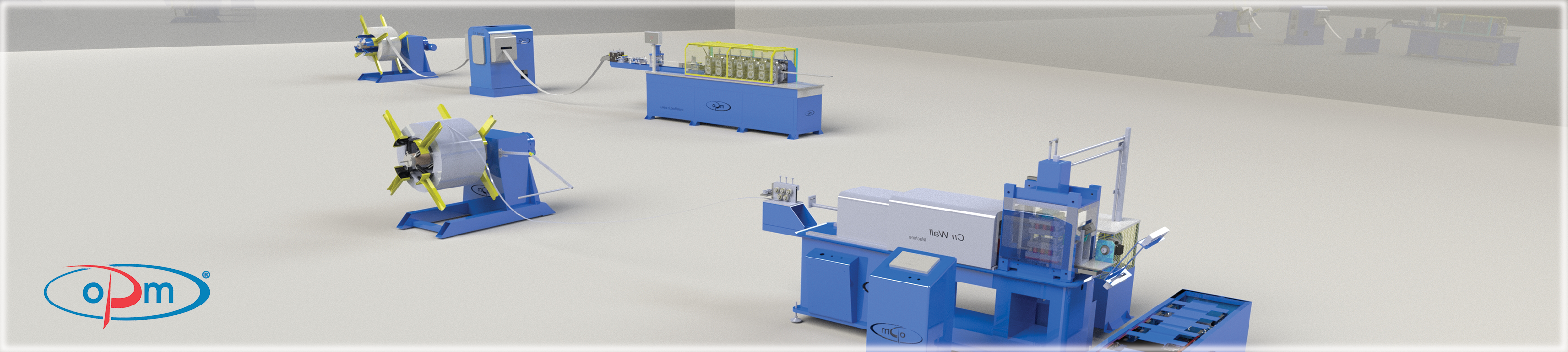

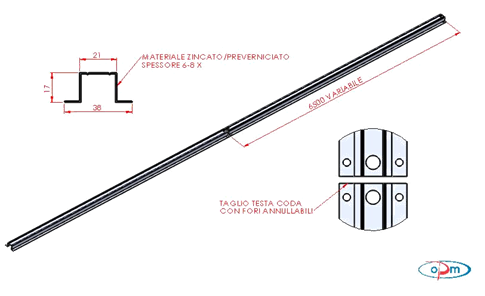

The OPM automatic profiling machine is designed to create U and Omega profiles in galvanized-prepainted sheet metal with a thickness of 6-8/x. A productivity of about 20m-25m/minute is expected.

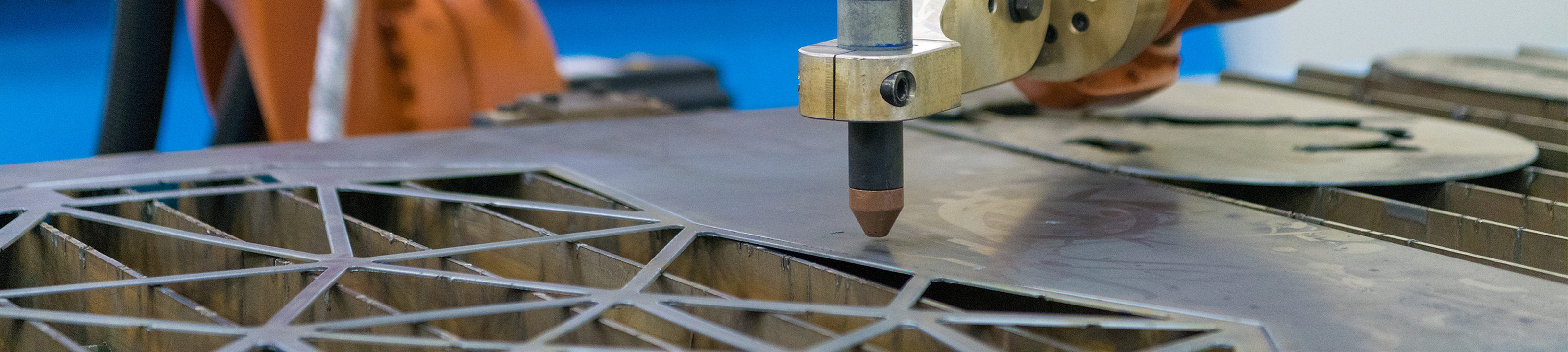

The machine compliant with CE standards consists of a base, a system of rollers, a belt centering system, a hydraulic unit, a hydraulic system, a hydraulic unit for cutting and drilling, a manual hole canceller, an electrical panel, and a sensor system for detecting errors or malfunctions.

From the feasibility study carried out, the work sequence is divided as follows:

Firstly, the coil is loaded onto a motorized unwinder. Subsequently the strip passes through the centering system which allows the strip to be worked with precision by the roller system. Now the belt is ready to be processed.

The whole work process is controlled and managed by a PLC which allows you to command all the operations of the machine and to automatically detect failures or malfunctions. Above all the PLC is very important to start the automated processing. This consists of motorized rollers controlled in feedback via encoder to guarantee an accuracy of +/- 0.5mm. Once the desired profiling has been obtained, the belt passes through the hydraulic unit to make the cut and the head tail holes with a diameter of 4.2mm and 8mm which are possibly manually cancelled.

The machine is also composed of a specially created electrical panel which allows you to centralize all the electrical peripherals by concentrating the power and control units in a single dedicated cabinet. This allows easy maintenance and immediate diagnostics in the event of a malfunction.

The brain of the profiling is the PLC which deals with the management and optimization of production, interfacing and connecting the various parts of the machine and the moving parts, as well as manages the active safety devices and detection sensors. To proceed with production it is necessary to set the technical characteristics of the product to the PLC, i.e. establish the length of the profile, the quantity to be produced, and it is then possible, with software (industry 4.0), to monitor the production and processing status of the machine. Once the data have been set on the PLC, by pressing the START key the production starts and proceeds automatically starting from the coil.

The machine is also equipped with photocells which control the effective production of the profile.

The production data is stored in real time, so if the tape runs out, the profile stops and communicates the emergency, and when production is resumed, it is restored from the last profile produced and thus completes the previously set production cycle.

The system is equipped with an emergency button to block the machine in the event of an anomaly that is not automatically detected.

The active and passive safety devices ensure that the operator is protected during processing by certifying the machine as CE, characterizing the machine as safe in order to access the benefits of Italian and European law.

The motorized unwinder has a maximum capacity of 1Ton, and has the possibility of adjusting the operating speed via inverter, it also integrates sensors for detecting the tape out of position to stop both the reel and the profile in case it occurs for some reason an abnormal situation while protecting the machine from damage. In addition, the machine integrate a pneumatic system to cancel the punches drilling, if necessary.

The profile is designed to also produce a U-shaped profile 8 ÷ 10/x; this is possible by replacing some components, such as the profiling rollers that are to be mounted on the profile, the dedicated twister to correct any twisting of the profile, a drilling unit to make an embossed hole, and a cutting die dedicated to the type of profile that it must be mounted on the hydraulic unit present on the profile.

- Unwinder capacity: 2,000 kg

- Maximum working width: 350 mm

- Inner roll diameter: 480-750 mm

- Line drive power: 8.5 -12.5kw

- Roll forming speed: 25 m/min

- Length tolerance: ±1mm

- Sheet thickness: 0.3-4 mm

- Number of stations: 6-35

- Shaft diameter: 45-55 mm

- Tool material: 42CrMo4 nitrided to 64HRC

- Shaft material: 42CrMo4 28 HRC;

- Blade material: X210Cr12 58-60 HRC

- Transmission type: gear transmission

- Cutting type: Hydraulic shear

- Process control: SCHNEIDER ELECTIIC electronics, PLC Tex Computer

SEE ALSO