Automatic Machine to produce wedges - Wedges – Automatic Machine to produce wedges for formworks

FEATURES

Wedges for Formworks

- Automatic Machine to produce wedges

- The machine is fully automatic

- It has a productivity of ~45 pieces/min

- It is fully electronic and the productivity is managed by software

- Possibility to set the number of wedges to be produced

The machine is designed to to make wedges for construction. It is expected a productivity of about 45 pcs/min: each molding cycle produces 2 wedges, without scrap.

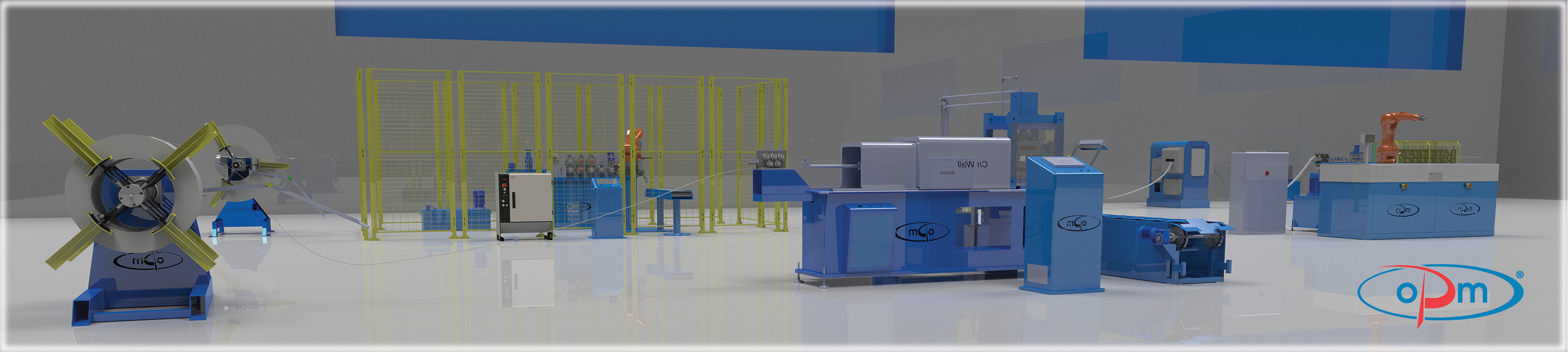

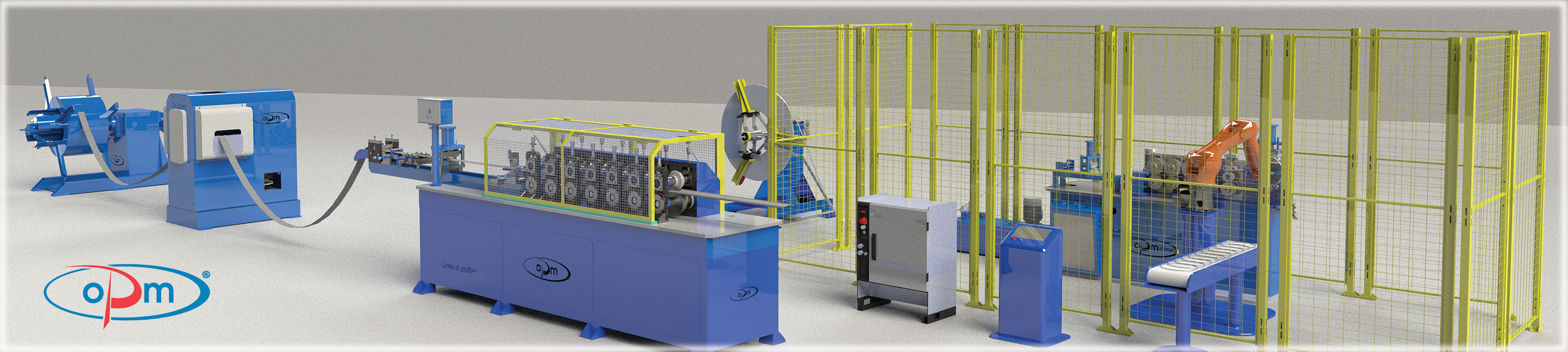

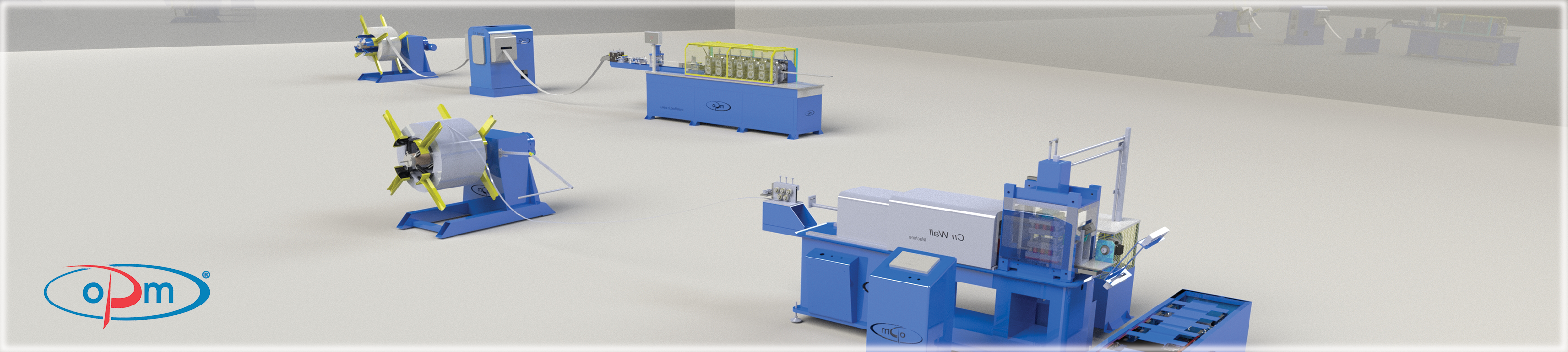

The machine compliant with CE regulations consists of a motorized decoiler, an hydraulic unit, a hydraulic working machine, a mold, an electronic advance/straightener, an electrical panel, a sensor system for detecting the correct functioning of the machine, and a PLC with dedicated software to manage and optimize the work process.

From the feasibility study carried out, the work sequence is divided as follows:

The coil is loaded onto a motorized decoiler, the tape then passes through the centering system and through the electronic feeder / straightener that allows the tape to be worked with precision. Subsequently, a molding cycle takes place, after which 2 wedges are produced, without scrap.

The whole work process is controlled and managed by a PLC that allows you to control all the operations of the machine and to detect faults or malfunctions automatically and above all to start the automated processing.

The electronic feeder that we offer also incorporates rollers designed to straighten the tape in order to make the machine very compact. All the rollers are motorized and this allows a great precision and tape feed speed.

The specially created electrical panel allows you to centralize all electrical peripherals by concentrating the power and control units in a single dedicated cabinet. This allows easy maintenance and immediate diagnostics in case of technical intervention.

The brain of the machine is the PLC that deals with the management and optimization of production, interfacing and connecting the various parts of the machine and the moving parts, as well as managing the active safety devices and detection sensors. To proceed with the production it is necessary to set the quantity to be produced. Once the data has been set to the PLC, by pressing the START key the production starts and proceeds automatically starting from the coil.

The production data are stored in real time, so if the tape runs out, the machine stops and communicates the emergency, and when production is then resumed, it is restored from the last piece produced and thus completes the production cycle set previously.

The machine is also equipped with photocells that check the actual production of the wedges.

The system is equipped with an emergency button to block the machine in the event of an anomaly not automatically detected.

The active and passive safety devices ensure that the operator is protected during processing by certifying the CE machine, characterizing the machine as safe to access the benefits of Italian and European law.

MATERIAL: dark raw iron

THICKNESS: 4 mm

SEE ALSO oPm Paletti/Cunei – Automatic machine to produce Stirrups and Wedges for Formwork

SUBsCRIBE TO OUR YOUTUBE CHANNEL