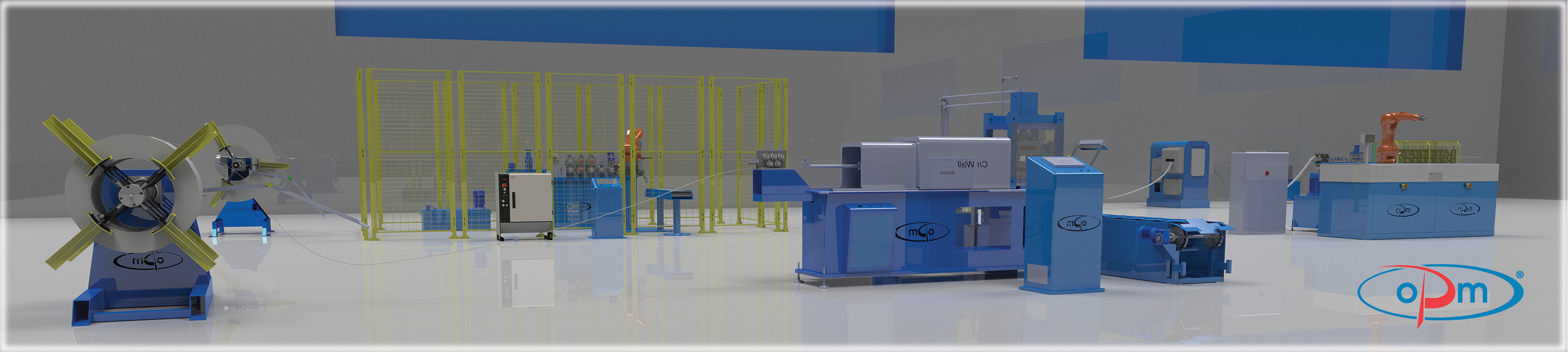

- AUTOMATIC PLANT FOR TUBE MACHINING

FEATURES

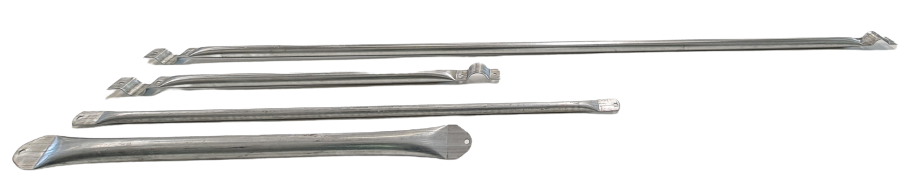

The OPM automatic machine is designed to process pipes of different diameters Ø27- Ø32- Ø42- Ø48 and different lengths (max 10m). Specifically, the machine makes the tie-rods, tie-backs, and ridges by cutting/tailing at the ends of the pipe. The processing material is iron with a thickness of min 1.2mm and max 2mm. A productivity of about 1,000 pieces per day is expected (productivity decreases with increasing length).

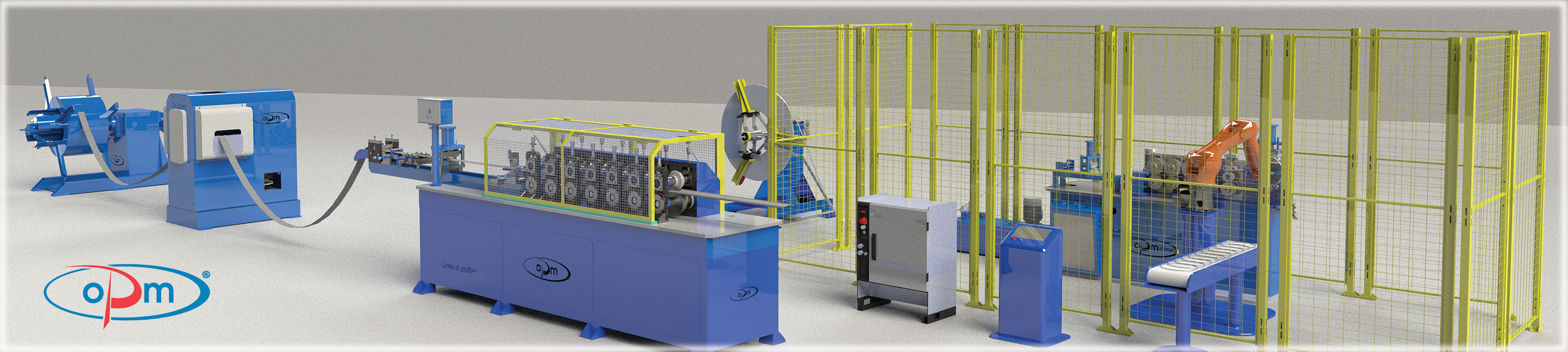

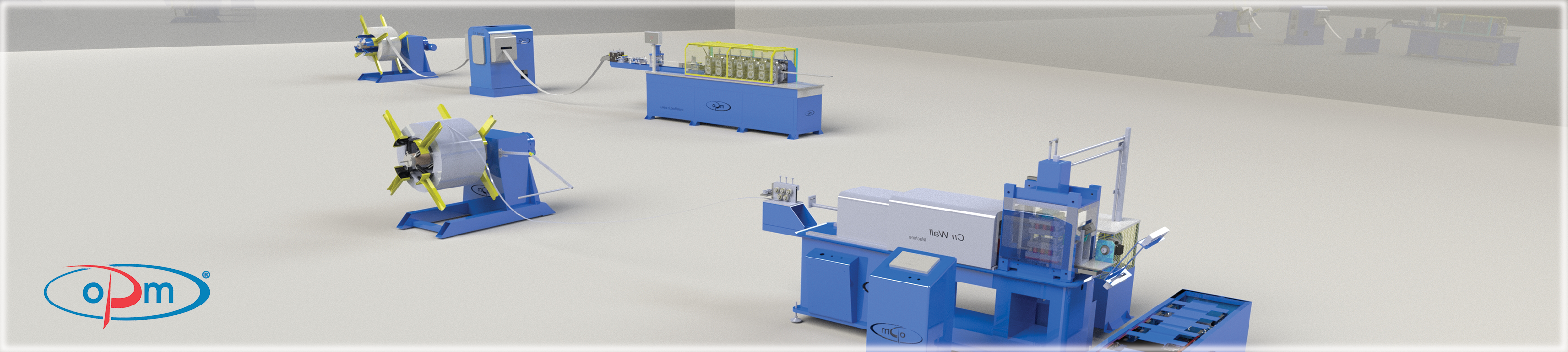

The machine, which complies with CE regulations, consists of a base, a motorised tube bundle loader, a hydraulic power unit, two roller conveyors, one of which with a pneumatic chute, a hydraulic system, a lubrication system, a pneumatic system, two motorised tube feed systems, a hydraulic unit with interchangeable dies for cutting and head/tail holes, an electrical panel, a PLC with dedicated software to manage and optimise the work process, a motorised product pick-up, and a sensor system to detect the operating status.

The work sequence is as follows:

To proceed, the mould dedicated to the specific machining is mounted on the hydraulic unit, and the production data is entered into the PLC, i.e. the type of machining to be performed, the desired lengths, and the quantity to be produced. By pressing the START button, production starts automatically. The tubes are loaded onto the motorised loader, positioned on the roller conveyor and moved by a special feed system to the working unit. Processing is then carried out at both ends. Finally, once the processing has been carried out, the tube is moved and positioned on the roller conveyor with a pneumatic chute, which discharges the tube into the product collector. The machine works automatically until the completion of the production cycle set at the PLC.

The brain of the machine is the PLC, which is responsible for managing and optimising production, interfacing and connecting the various parts of the machine and moving parts, as well as managing active safety and sensing sensors.

In order to proceed with production, it is necessary to set the technical characteristics of the product from the PLC, and it is then possible, with software (Industry 4.0), to monitor the production data and the processing status of the machine in real time on your computer. Once the data has been set at the PLC, pressing START starts production and proceeds automatically.

The machine incorporates a specially designed electrical panel that allows all electrical peripherals to be centralised by concentrating the power and control units in a single dedicated cabinet. This allows easy maintenance and immediate diagnostics in the event of a technical intervention.

The system is equipped with an emergency button to stop the machine at any time. There are also safety photocells to protect the operator during processing, certifying the machine CE, and characterising the machine as safe to access the benefits of Italian and European law.

SEE ALSO