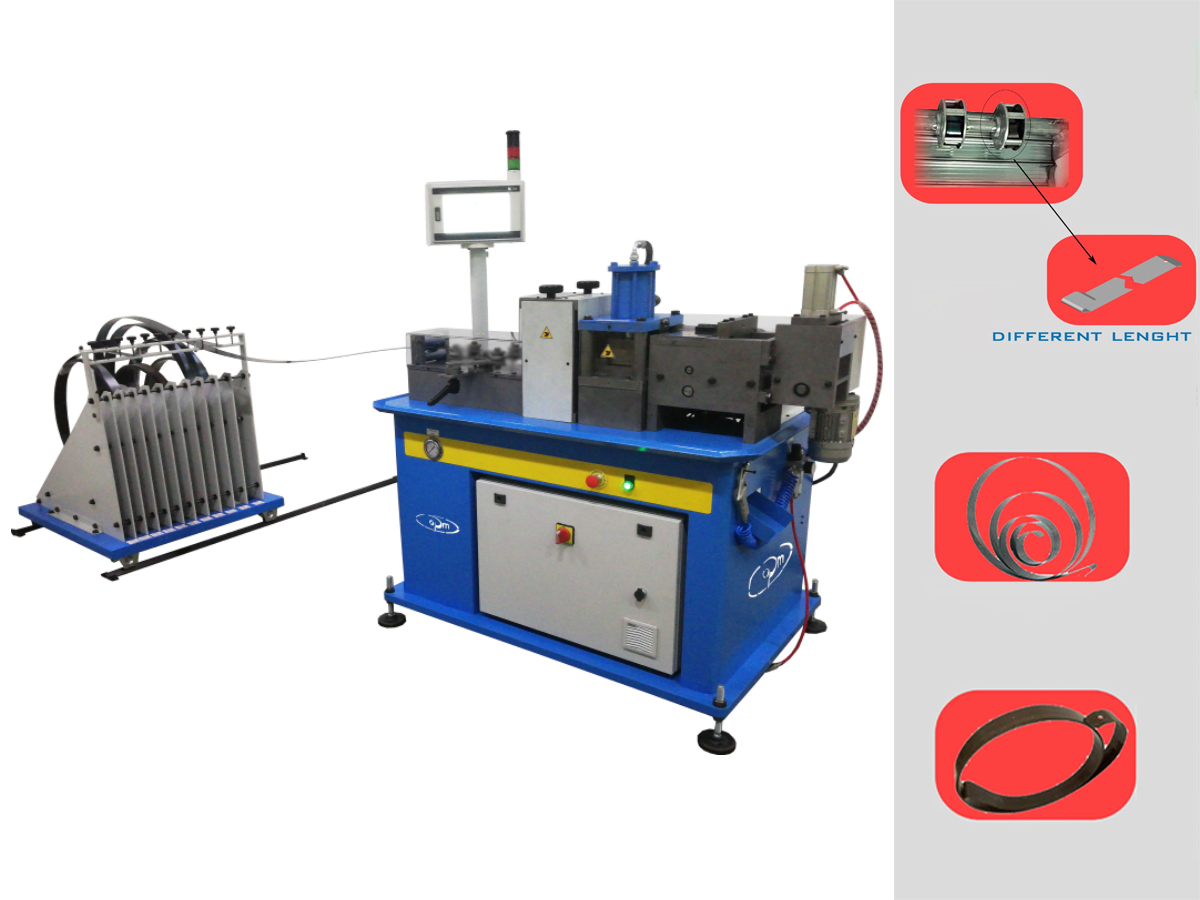

UTS - Automatic machine for roller shutter spring

FEATURES

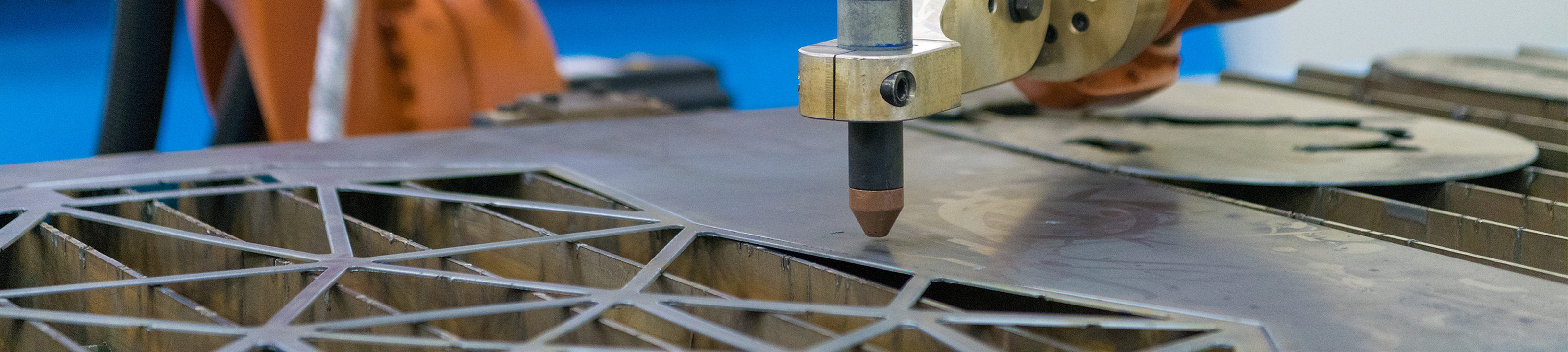

Automatic hydraulic machine for the complete processing and production of roller shutter spring from coils, performing bending, drilling, chamfering, and cutting of various types of springs for roller shutters.

- Automatic hydraulic machine for the complete processing and production of roller shutter spring starting from coils, to carry out bending, drilling, smoothing and shearing operations of various types of springs for rolling shutters

- Complete of software system for complete management of production and tape decolier

- Complete with hydraulic unit and electrical panel

- Possibility of counting the pieces produced with a specific counter

- Power supply 4kW / 400 V

- Productivity :about 3 pieces for minute

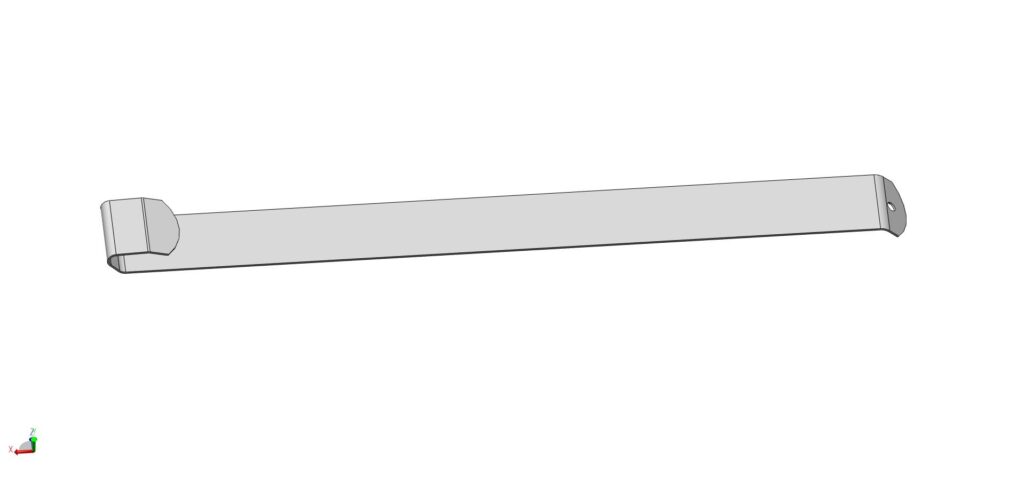

- Material: spring steel. Spring width Min 40 mm – Max 80 mm. Spring thickness Min 1 mm – Max 1.4 mm

ROLLER SHUTTER SPRING MACHINE DESCRIPTION:

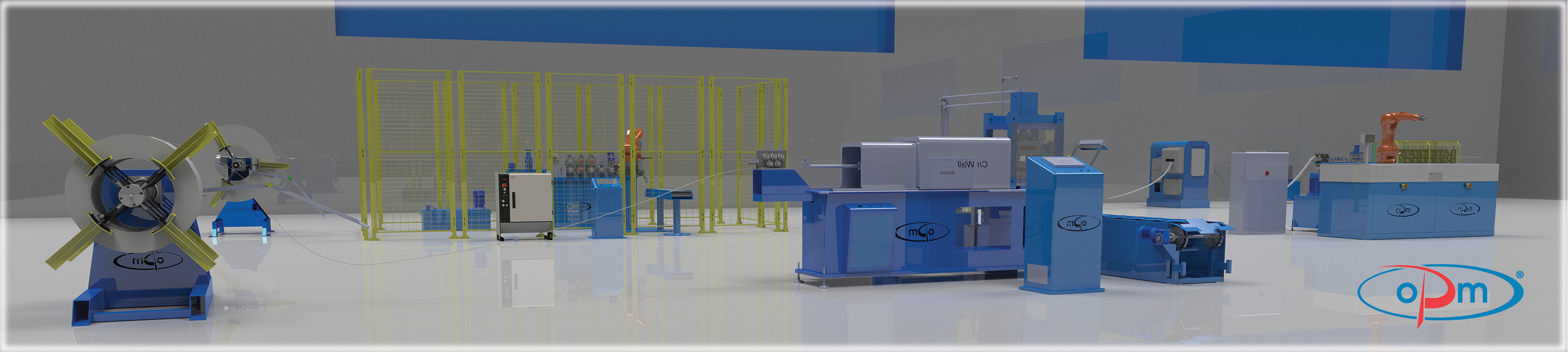

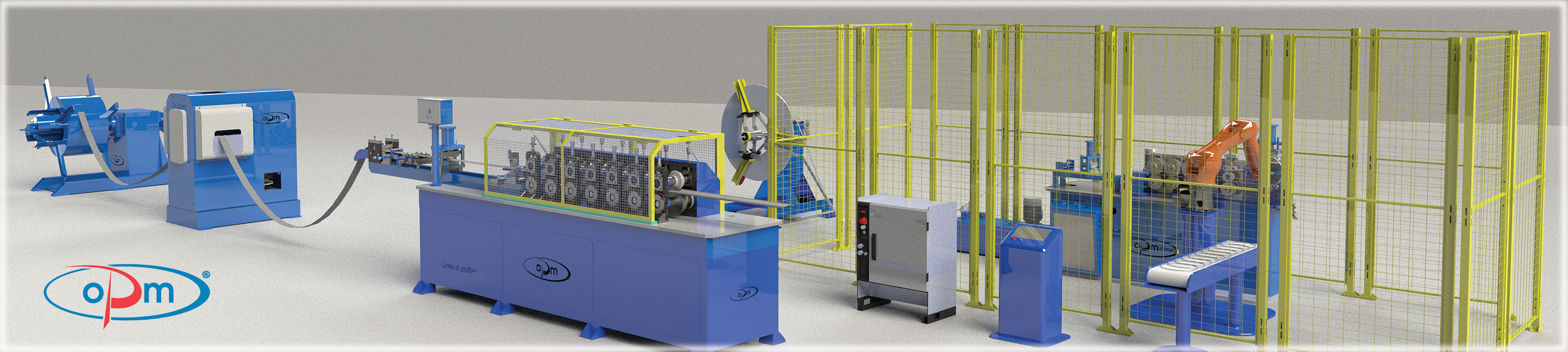

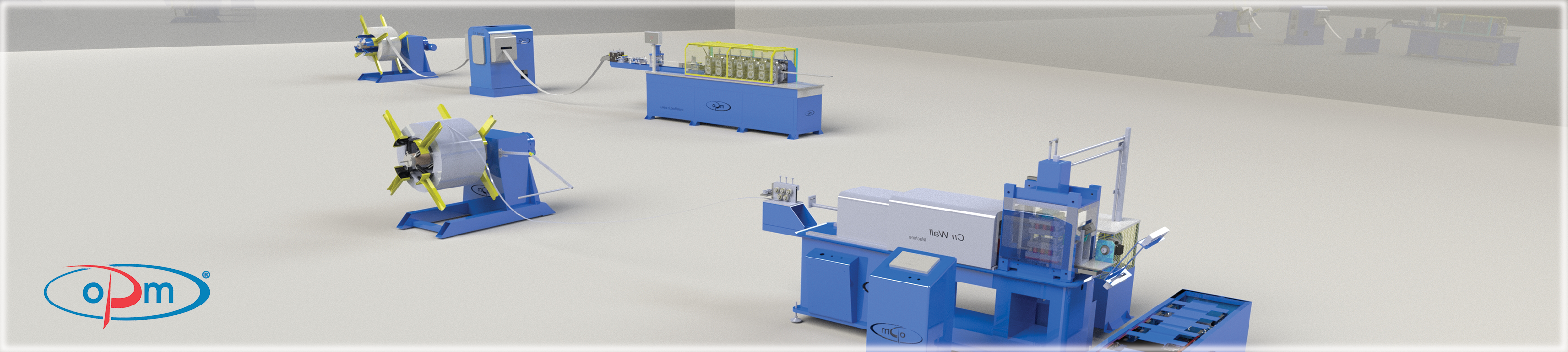

The CE-complaint machine consists of a hydraulic power unit, hydraulic system, feed system, bending system, a mold, an electrical panel, a PLC with dedicated software for comprehensive roller shutter spring production management, and a sensor system for detecting potential errors or malfunctions.

The innovative of our shutter spring bending machine lies in the automatic ejection system that expels the freshly produced spring at the end of the processing cycle. To ensure fully autonomous operation, a sensor system detects the actual ejection of the finished product, signaling any failure to eject the spring with audible alert. This fully automated system frees the operator, who is only tasked with intervening in case of anomalies.

Within the machine’s software, one can store desired bend angles and feed advancements to achieve a spring profile deemed optimal. Once data is entered, it can be recalled whenever necessary, streamlining the workflow process.

The dedicated software enables the counting of produced roller shutter spring with a built-in counter, and a computer-connected feeder allows setting the spring length, making the machine automatic. Additionally, a calculation function is present to determine the number of springs needed for shutter construction, significantly easing data setup for processing.

The bending characteristics of the spring and the input parameters stored in the software are memorized by the machine, allowing the operator to easily recall data for quick and efficient processing.

The machine can be equipped with a 7-position decoiler, accommodating tapes of various spring sizes.

Implemented with software capable of calculating the shutter weight, the machine suggests a choice of suitable springs and boxes for the entered shutter dimensions, based on resettable tables (modifiable according to the customer experience). This provides even novice operators with an overview of potential spring-box combinations, maximizing the use of the company warehouse.

The automated machine, which cuts, bevels, drills and bends springs for shutters, can be integrated with optional software (Industry 4.0) to monitor production data and the machine’s processing status in real-time on your computer.

You could also be interested in Working center/ automatic machine for drilling and working tubes/ rolling shutter axes

Explore our systems and solution for creating closures for construction: our machines enable the production of all components for armored doors and shutters. Each machine meets the production needs of customers, from manual to automatic machines, and even robotic systems. Learn more about machines for creating closures for construction