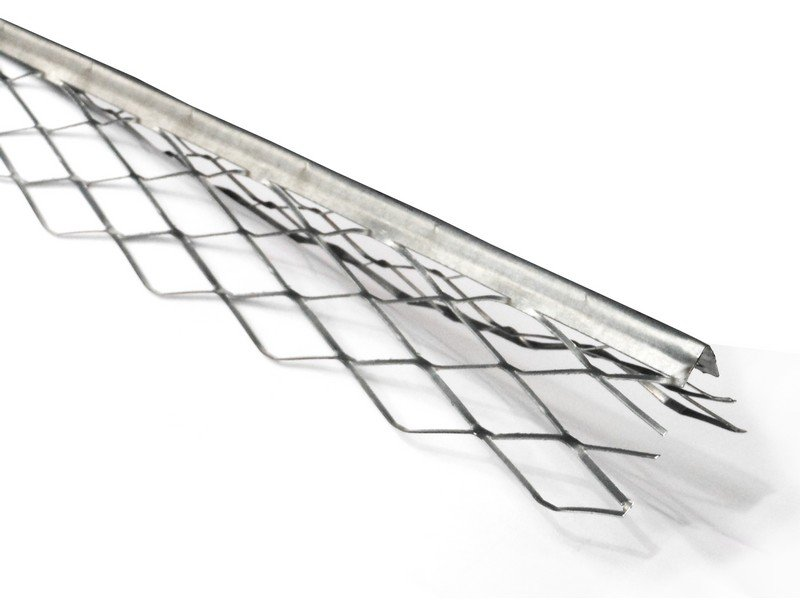

AUTOMATIC MACHINE FOR IRON CORNER GUARDS - Corner Beads Roll Forming Machine with Eccentric Press

FEATURES

Corner Beads Roll Forming Machine

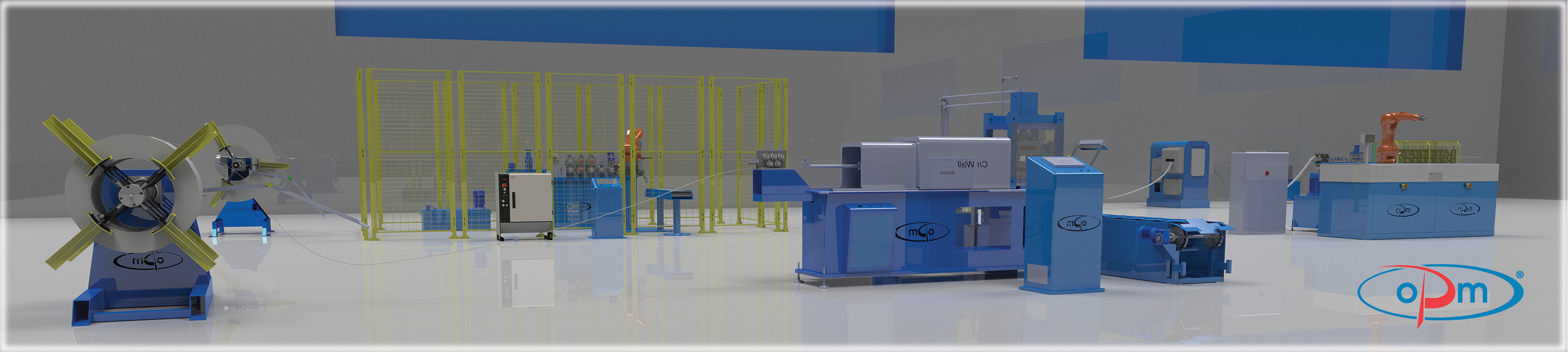

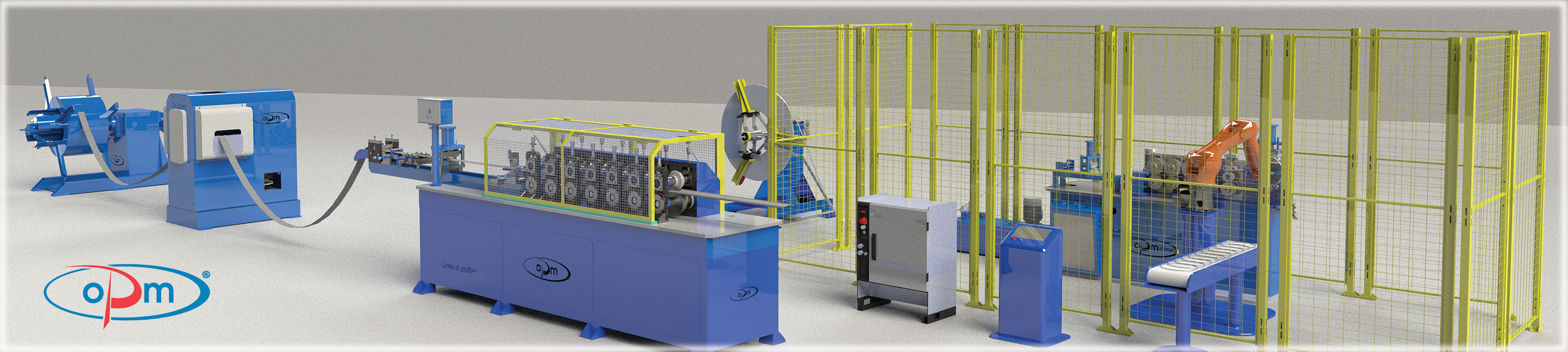

Discover the OPM automatic profiling plant, meticulously engineered for the efficient production of Corner Beads profiles and perforated profiles for plaster guides. Designed for optimal performance, the plant boasts a remarkable productivity rate of approximately 20 meters per minute for both the perforated and angle profiles, using high-quality galvanized steel with a 0.4mm thickness. Our advanced automatic roll forming machine with eccentric press is a game-changer in the construction industry, specifically designed to produce top-quality corner beads.

Manufactured entirely in Italy at OPM’s headquarters, the plant adheres to CE regulations, ensuring reliability and compliance. It comprises a robust base, an eccentric press working unit equipped with molds for creating the ‘mesh’ and perforated profiles, dedicated roll systems for profiling both profiles, a strip centring system with electronic rectifier, slitting units for both angled and perforated profiles, an electrical cabinet, a PLC for streamlined production management, and a sensor system for error detection.

Corner Beads Roll Forming Machine Workflow

The seamless workflow, identified through a comprehensive feasibility study, unfolds as follows:

- Loading the coil onto the motorized unwinder.

- Passage through the centring system and the electronic rectifier, ensuring precise processing by the press and roller system.

- Entering the working unit to create the ‘mesh’ net.

- Automated profiling of the bent profile.

The entire operational workflow is seamlessly controlled by a PLC, ensuring precision and efficiency. Automatic fault detection and initiation of automated processing make this machine stand out.

The profile is crafted using pairs of bending rollers, precisely motorized and feedback-controlled by encoders to achieve an outstanding accuracy of +/- 0.5mm. The process is completed with a cutting unit that precisely shears the profile to the predetermined length set in the PLC during data input.

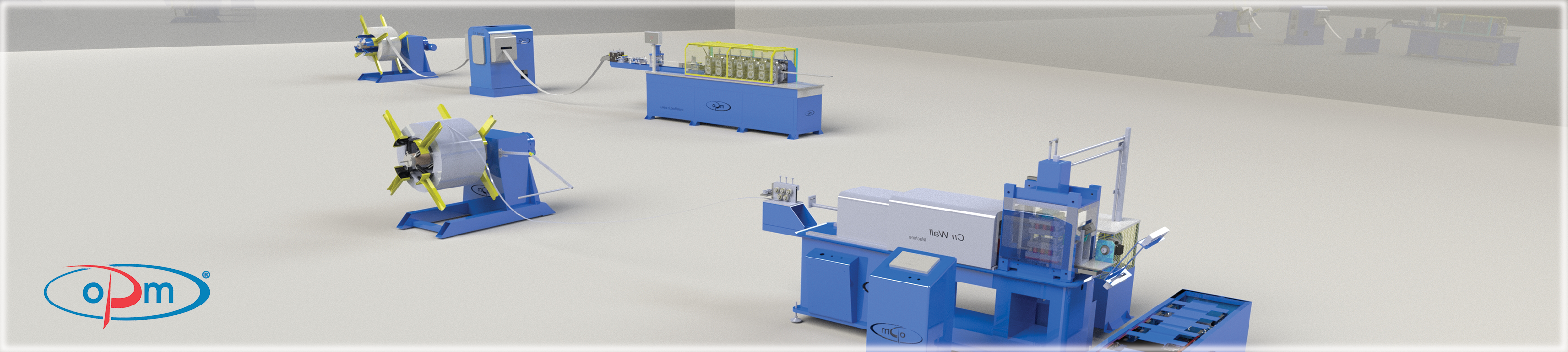

For creating perforated profiles, the machine requires the profiling roller kit, drilling mold, and a dedicated cutting unit. Setting production data in the PLC and hitting START triggers the automatic production from the coil. The drilling unit first processes the profile, followed by the profile cutter shaping it to the desired section. The final touch involves cutting the profile to the pre-set length.

Our machine boasts a specially designed electrical cabinet, centralizing all electrical peripherals for easy maintenance and swift diagnostics in case of malfunctions.

The PLC serves as the brain of the profile, managing and optimizing production, connecting machine components, overseeing active safety features, and handling detection sensors. To initiate production, simply input the technical characteristics – type of profile, length, and quantity – into the PLC. Press START, and production automatically begins from the coil.

Equipped with photocells to monitor profile production, our machine ensures real-time data storage. In case of belt depletion, the machine halts, signaling an emergency. Upon resumption, production continues from the last completed profile, completing the pre-set production cycle.

Safety is paramount, featuring an emergency button to manually stop the machine during unforeseen faults. Active and passive safety devices certify CE compliance, ensuring adherence to Italian and European regulations for a secure working environment.

Revolutionize your drywall corner bead production with our advanced roll forming machine, delivering precision, efficiency, and compliance.

SUBSCRIBE OUR YOUTUBE CHANNEL!

See also: