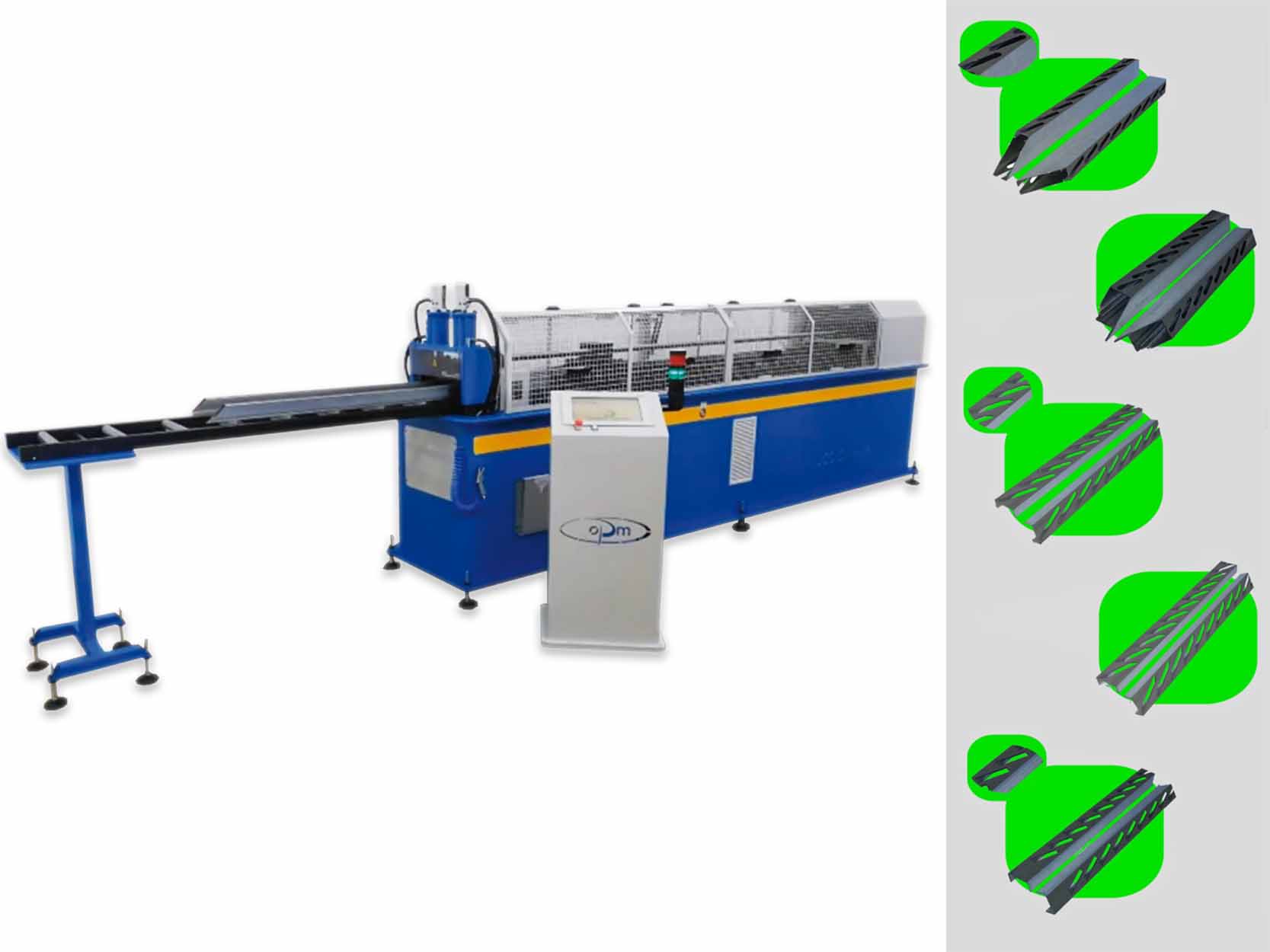

UCO-COMPUTER - Automatic Punching and Drilling Machine for Buttonhole

FEATURES

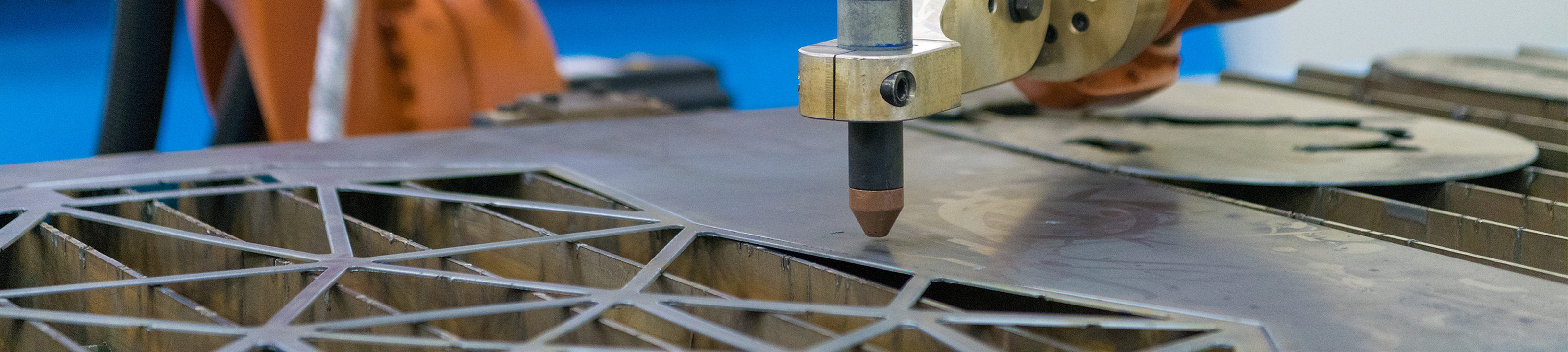

- Automatic hydraulic drilling machine and buttonhole machine for processing Persian profiles, to produce slots and holes of various types and sizes on Persian profiles

- Complete with dedicated software system for complete production management and automatic profile advancement system

- Complete with hydraulic unit and electrical panel

- Power supply 4kW / 400 V

- Productivity: 1 pair of 3m length bars in 1 and a half minutes

- Material: 60×40 profile

oPm machine is designed to realize the 60×10 slotting on iron bars of max lenght of 3 m. The machine processes two profiles simultaneously. it is expected a productivity of about 2 bars in 1 minute and 30 seconds.

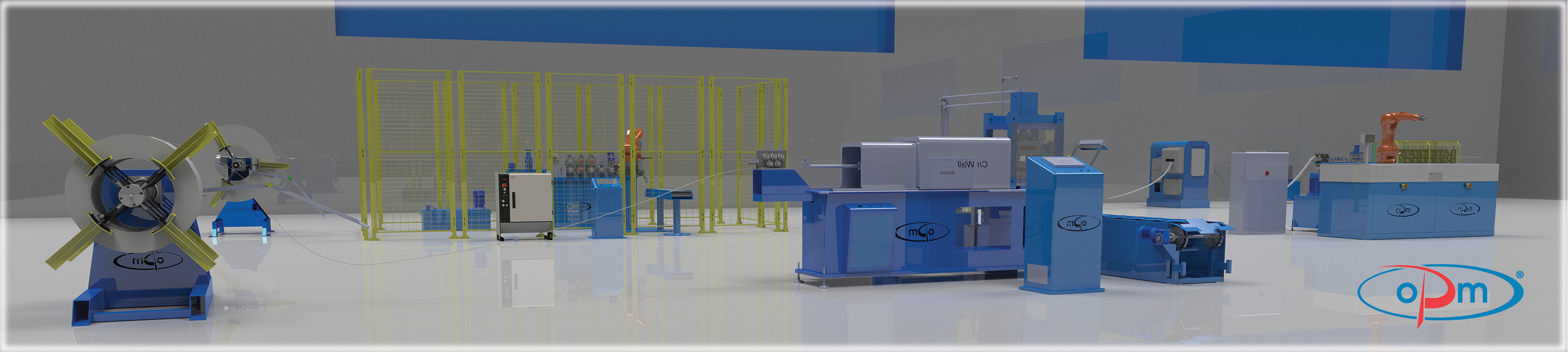

The machine, compliant with CE regulations, consist of a base, a Standard hydraulic power plant (With cooling system), an electrical panel, an hydraulic unit with two molds, a system of profile advancing, a PLC with dedicated software to manage and optimize the work process, a sensor system for detecting the correct functioning of the machine.

From the feasibility study carried out, the work sequence is divided as follows:

To proceed with the production it is necessary to set the technical characteristics of the product on the PLC: the length, the the size of the slot, and the number of pieces to be produced. By pressing the START key the production starts and proceeds automatically. An operator inserts the profiles manually and the advancing system moves the bars of the required height by placing them under the hydraulic unit provided with two molds, that proceeds to slot simultaneously the two profiles.

The machine allows you to adjust the pitch and offers the possibility to slot only the area where the oblique slats have to be inserted, allowing a better construction and a pleasant appearance of the product.

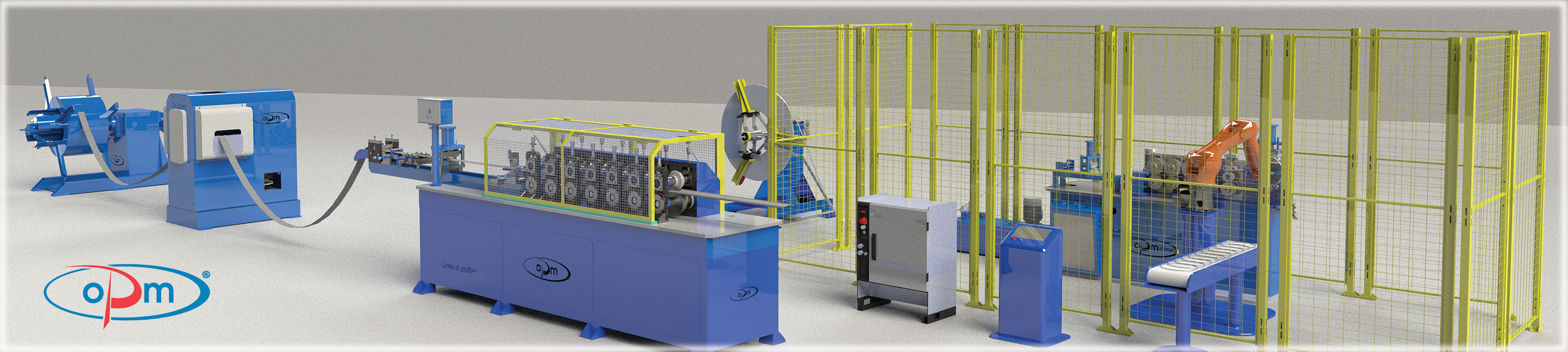

The brain of the machine is the PLC that deals with the management and optimization of production, interfacing and connecting the various parts of the machine and the moving parts, as well as managing the active safety devices and detection sensors.

Additionally, with optional software (Industry 4.0), you can monitor real-time production data and the machine’s work status on your computer.

The production data are stored in real time, so in the event of an anomaly, the machine stops and communicates the emergency, and when production is then resumed, it is restored from the last piece produced and thus completes the production cycle set previously.

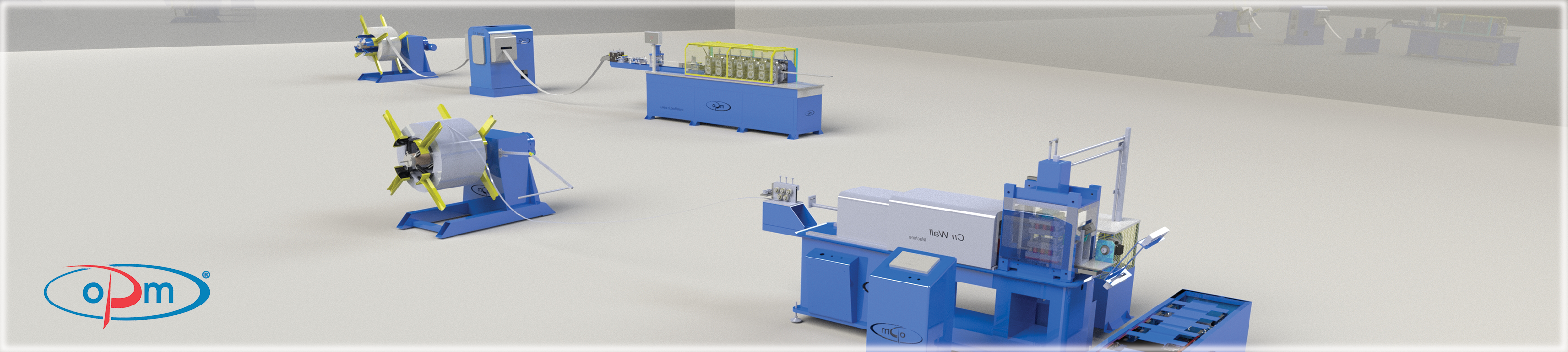

The specially created electrical panel allows you to centralize all electrical peripherals by concentrating the power and control units in a single dedicated cabinet. This allows easy maintenance and immediate diagnostics in case of technical intervention.